The journey of blood – on the road with Logistics

Blood donation in its simplest form is a beautiful thing: people take time out of their day to give blood for patients who need it. In reality, though, it’s far more complex.

The journey starts even before any of your blood is taken. It involves teams of people, fleets of vehicles and some fascinating science. It ends when the patient receives your blood, and you get that special text message.

So, if you want to find out more, join us in this series where we follow every stage of the journey: let’s look at the Logistics Department.

Using 220 liveried vehicles, driven by 250 drivers working in shifts 24 hours a day, seven days a week, NHS Blood and Transplant’s (NHSBT) Logistics Department transports everything from blood to biscuits between centres, team bases, session venues, hospitals and research laboratories, all over England.

With lorries, vans, estate cars and even minibuses, the fleet is always ready to transport our collection teams and equipment to sessions, and to deliver blood, platelets, plasma and samples – using blue lights if necessary – to the hospitals and patients that need them.

"My grandad used to be an ambulance driver, so I guess it is in my nature," said Mark, a driver from the Birmingham team. "As soon as I got my licence, I knew I wanted to become a driver."

He explained, "Working at NHS Blood and Transplant as a driver, you know you are doing something good; we deliver products that save lives.

"When you arrive for your shift you have to do a visual check around the vehicle, which is then captured on an E-pod (handheld driver terminal), inspecting the oil and brake fluid levels, engine coolant, washer water and tyre tread depth. Drivers also need to check that the blue lights and horns are working, which can be pretty loud! It is essential that we do safety checks on vehicles before driving them.

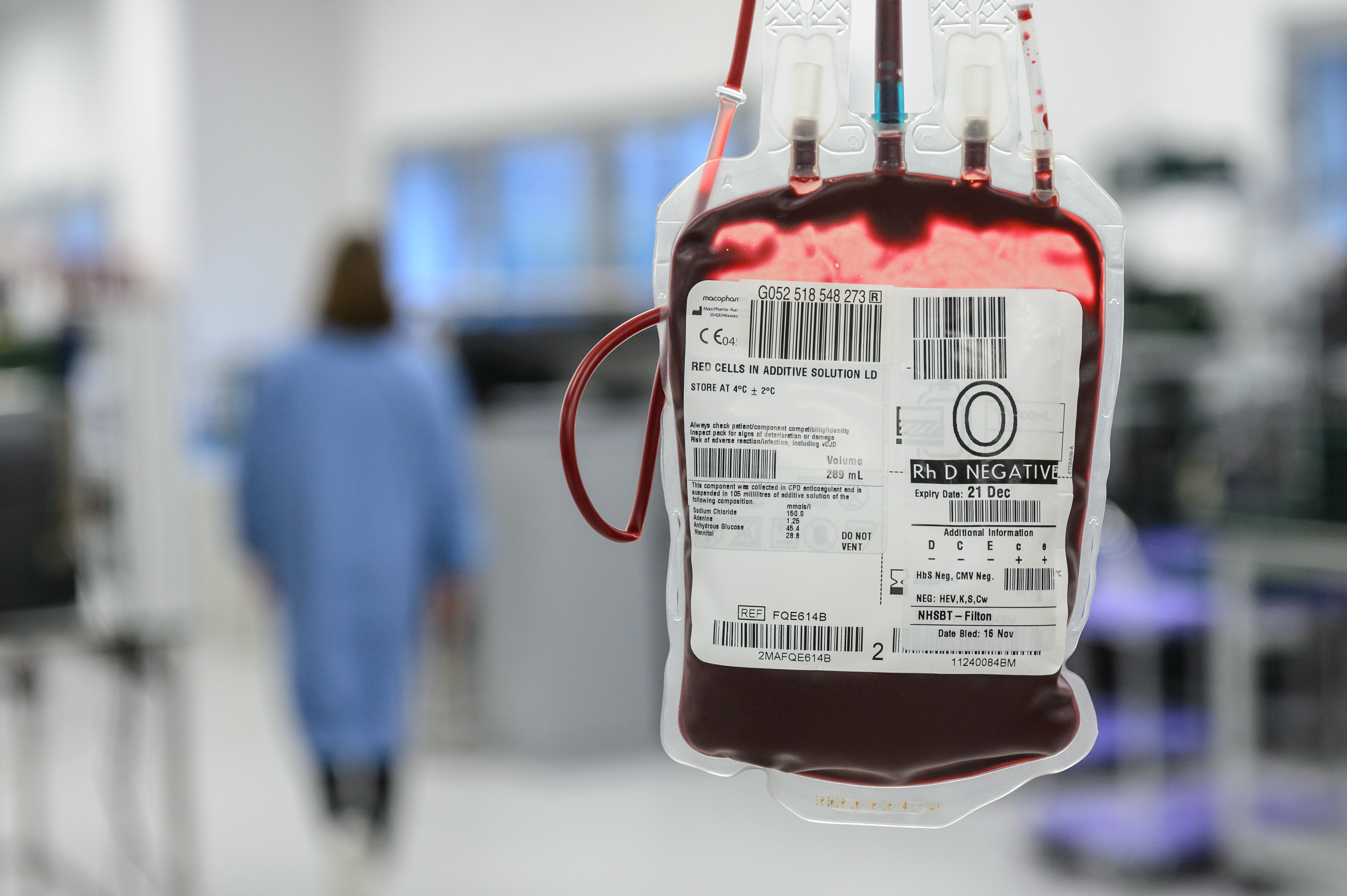

"Processed blood, plasma and platelets that need to be delivered to hospitals will be in Hospital Services ready for dispatch and waiting for the driver to load them onto the van.

"At the time of pick-up and drop-off, each driver has to check what has been loaded and unloaded onto the vehicle. Colleagues in Hospital Services use T2A (Tag to Asset) system to link the blood components to the containers that drivers pick up and deliver. Drivers use E-pods, which have a handheld barcode scanner, to scan the barcodes on the containers, so that they can be tracked.

"Each product has to be stored at a different temperature and therefore they are placed in special boxes, similar to cool packs. You can fit up to 10 units in each box. Different boxes are used for different travel times. For example, if a hospital is couple of hours away, you would use a bigger pack to store the products in, to keep them safe. All our vehicles are insulated to provide the protection the blood components need.

"We use Transport Management System (TMS) on our E-pods - it tells each driver which hospital they are going to be delivering to that day. All vehicles are equipped with four CCTV cameras and they, combined with our TMS system, are able to monitor all our performance including fuel consumption and driving style.

"We deliver to 340 hospitals nationally. And we might have to return to the same hospital more than once in a day. After delivering processed products to hospitals, we then go to the nearest blood collection sessions to pick up blood, plasma and platelets that have just been donated.

"We time our arrival to coincide with the staff breaks, and we get to know each other pretty well. During the pandemic, we’ve had to change processes to keep donors, collection staff and ourselves safe. Instead of arriving at session and going straight into the venue, we now have to wait until there are no more donors in the room. We have our temperatures taken, disinfect our hands and quickly take the blood packs to the van without stopping to talk.

"Donated blood, plasma and platelets are picked up twice a day from each venue, brought back to the base and stored at the appropriate temperature at one of our stock holding units. As not all centres are manufacturing sites, each evening, all products that have been donated that day are transferred to the nearest manufacturing site for testing and processing in vehicles called BMV’s which are temperature controlled lorries. The same driver then brings the processed products back to our stock holding units, ready to be sent to hospitals."

Emergency delivery

Mark said, “Most of our deliveries are made as part of a regular schedule of visits to hospitals, but sometimes blood components are needed at very short notice. And that is when we can use blue lights and horns on the vehicles. To use the blue lights, we need to have authorisation from the hospital. It mainly happens when a consultant asks for products they urgently need for a specific patient.

We have to be very careful when driving as we do not want to endanger ourselves or the public, but also the products that we carry. It might be the only available bag of blood that is the perfect match for the patient in need. What we carry is priceless.

"All drivers are ‘blue light trained’. We go through a rigorous training and a refresher training every two years to ensure that we are safe and comply with all the legal regulations. During the blue light delivery, our drivers are not allowed to speed. We can go through red lights, but they have to be treated as ‘give way’. And we can use both sides of a keep left signal or bollard and bus lanes but only in an emergency, but again must proceed with care.

"We have to be very careful when driving as we do not want to endanger ourselves or the public, but also the products that we carry. It might be the only available bag of blood that is the perfect match for the patient in need. What we carry is priceless."

Paul Taylor, Assistant Director for Logistics says, "During the pandemic, our teams have pulled out all the stops to make sure we continue to supply hospitals and all areas of NHSBT with the products they need. Our drivers have helped with setting up the new convalescent plasma centres, where we collect plasma from those who had COVID-19 to help the most vulnerable, whilst still supporting day-to-day operations.

"Last year, NHSBT made over 136,000 deliveries to hospitals around the country and our drivers made over 2,200 blue light deliveries.

"I would like to thank all colleagues in Logistics for their hard work and dedication during this challenging time."

In the last six months, Logistics Department delivered an increasing amount of Personal Protective Equipment that was provided by our three warehouses across the country including;

- 1,200,000 pairs of gloves

- 7,600 aprons

- 615,000 face masks

- 12,000 small and large hand gels

- 19,000 packs (or 1.9 million sheets)

More recently our three warehouse sites have received more than 6,000 lateral flow test kits for Covid-19 testing of our colleagues. These were prepared for dispatch and transported to blood collection teams, testing labs, manufacturing and our Logistics sites.

At the hospital

Here, Fatts Chowdhury, Consultant Haematologist at Imperial College Healthcare Trust and NHS Blood and Transplant, takes us through how blood products are used in hospitals.

Here, Fatts Chowdhury, Consultant Haematologist at Imperial College Healthcare Trust and NHS Blood and Transplant, takes us through how blood products are used in hospitals.

UK plasma to be made available for medicine production

Plasma collected during whole blood donation will soon be able to be used used to produce lifesaving treatments.

Book your appointment online

Book now

Other stories

Remarkable stories from the world of giving blood – be they from the research lab, the hospital bed, or the donor chair